How Does CNC Machining Work?

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove portions of a stock material till the desired custom part is made from the workpiece.

The machining process starts with the creation of a CAD (Computer-Aided Design) model of the desired part, which is then loaded into a CAM (Computer-Aided Manufacturing) software and converted to a set of computer instructions.

This set of instructions (or G-code) allows the machine to execute different cutting operations at high speed (thousands of RPM) till the desired custom part is made.

How Does CNC Machining Compare to 3D Printing?

Both CNC machining and 3D printing rely on CAD files and computer inputs to transform a starting material into desired custom parts. However, unlike the subtractive CNC machining process, 3D printing is an additive machining process. It revolves around adding materials in layers to build the desired custom part.

CNC machining offers a wide range of material options, whereas 3D printing only works with plastics, polymers, and a few metals that are available in powdered form. Additionally, CNC machined parts are usually stronger than 3D printed parts; as such, CNC machining is ideal for prototyping and production of functional parts.

What are the Different Types of CNC Machining?

CNC machines come in many varieties, with each type having its unique functions.

CNC turning and milling machines feature built-in tools for cutting and drilling the workpiece till the custom CNC part is made. They are available in 3-, 4-, and 5-axis configurations, depending on the part complexity.

The CNC milling process involves the workpiece being held in place while the cutting tools rotate around it, whereas in CNC turning, the workpiece is rotated around the fixed cutting tools to create the desired shape.

Unlike CNC milling and turning machines that rely on cutting tools, CNC Electric Discharge Machines (EDM) utilize electric sparks to manipulate materials into the desired shape.

-

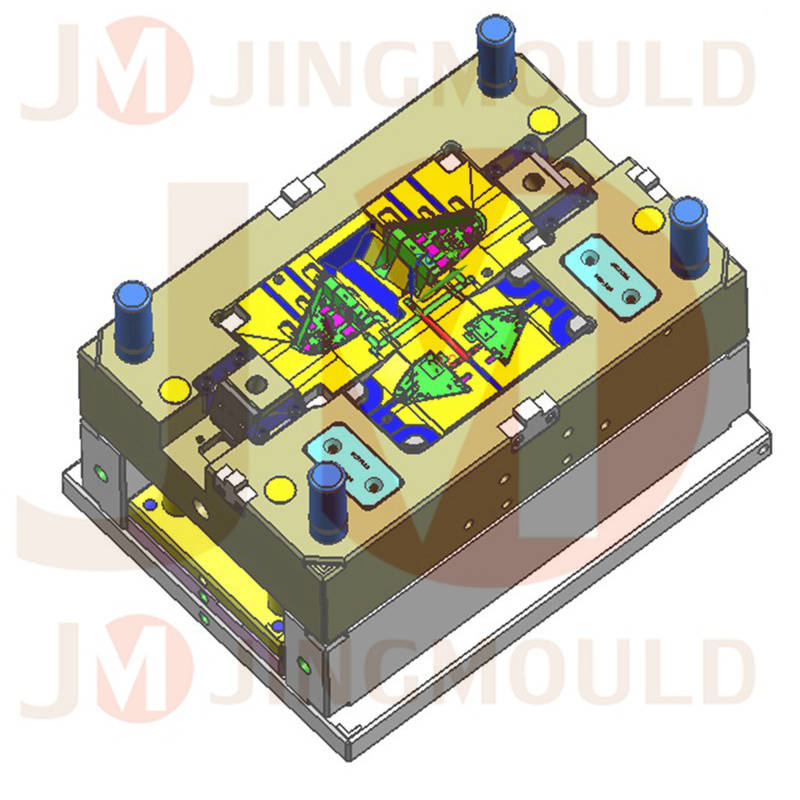

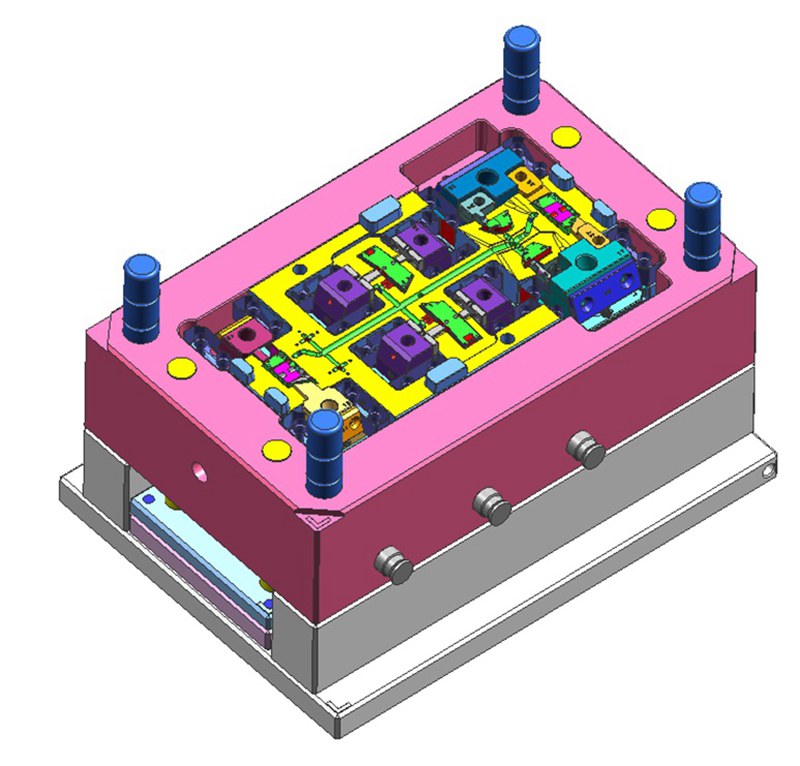

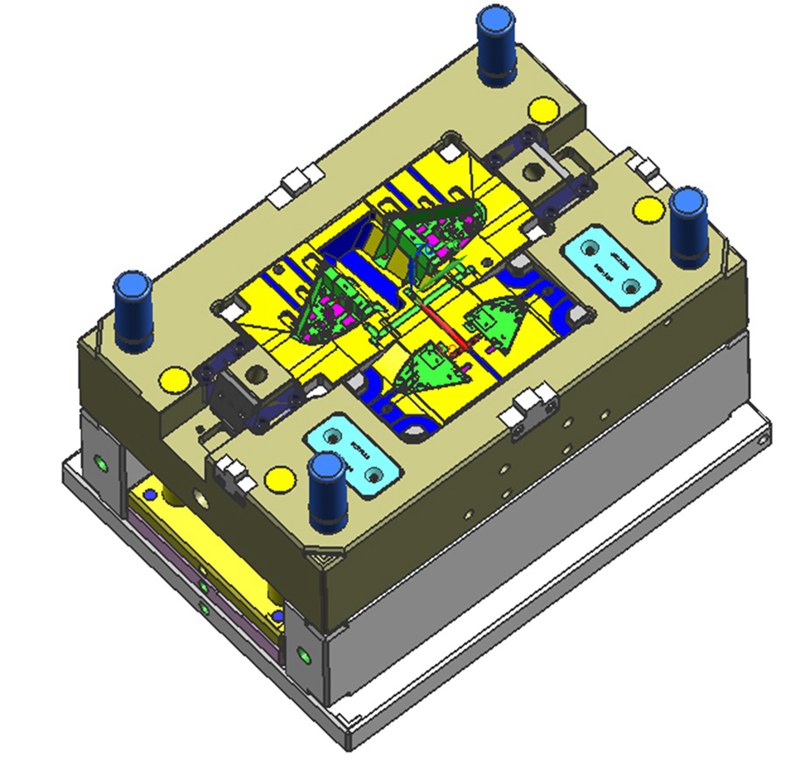

Design / Konstruktion für SpritzgusswekzeugDesign / Konstruktion für Spritzgusswekzeug Der Formenbau für den Spritzgusshersteller ...

Design / Konstruktion für SpritzgusswekzeugDesign / Konstruktion für Spritzgusswekzeug Der Formenbau für den Spritzgusshersteller ...Mögen Sie ?0

Weiterlesen -

Mold design for injection moldingMold design for injection molding manufacturer Jingmould offers a wide range design of mold, tooli...

Mold design for injection moldingMold design for injection molding manufacturer Jingmould offers a wide range design of mold, tooli...Mögen Sie ?0

Weiterlesen -

2022 Preferred Quality Supplier Award from ABB ChinaIt is a great honor for us to receive this special award. Thanks to the hard work of Jingmould te...

2022 Preferred Quality Supplier Award from ABB ChinaIt is a great honor for us to receive this special award. Thanks to the hard work of Jingmould te...Mögen Sie ?0

Weiterlesen -

How CNC Machining Works: An OverviewHow Does CNC Machining Work? CNC machining is a subtractive manufacturing process that ...

How CNC Machining Works: An OverviewHow Does CNC Machining Work? CNC machining is a subtractive manufacturing process that ...Mögen Sie ?0

Weiterlesen -

Präzisions Pulvermetall Formteile aus ChinaIndividuelle Pulver- (Sinter-) metallteile nach Kundenzeichnung vom chinesischen Marktführer ...

Präzisions Pulvermetall Formteile aus ChinaIndividuelle Pulver- (Sinter-) metallteile nach Kundenzeichnung vom chinesischen Marktführer ...Mögen Sie ?0

Weiterlesen -

CNC Machining SERVICECNC Machining Jingmould offers high-precision CNC machining services with quick turnarounds. With...

CNC Machining SERVICECNC Machining Jingmould offers high-precision CNC machining services with quick turnarounds. With...Mögen Sie ?0

Weiterlesen